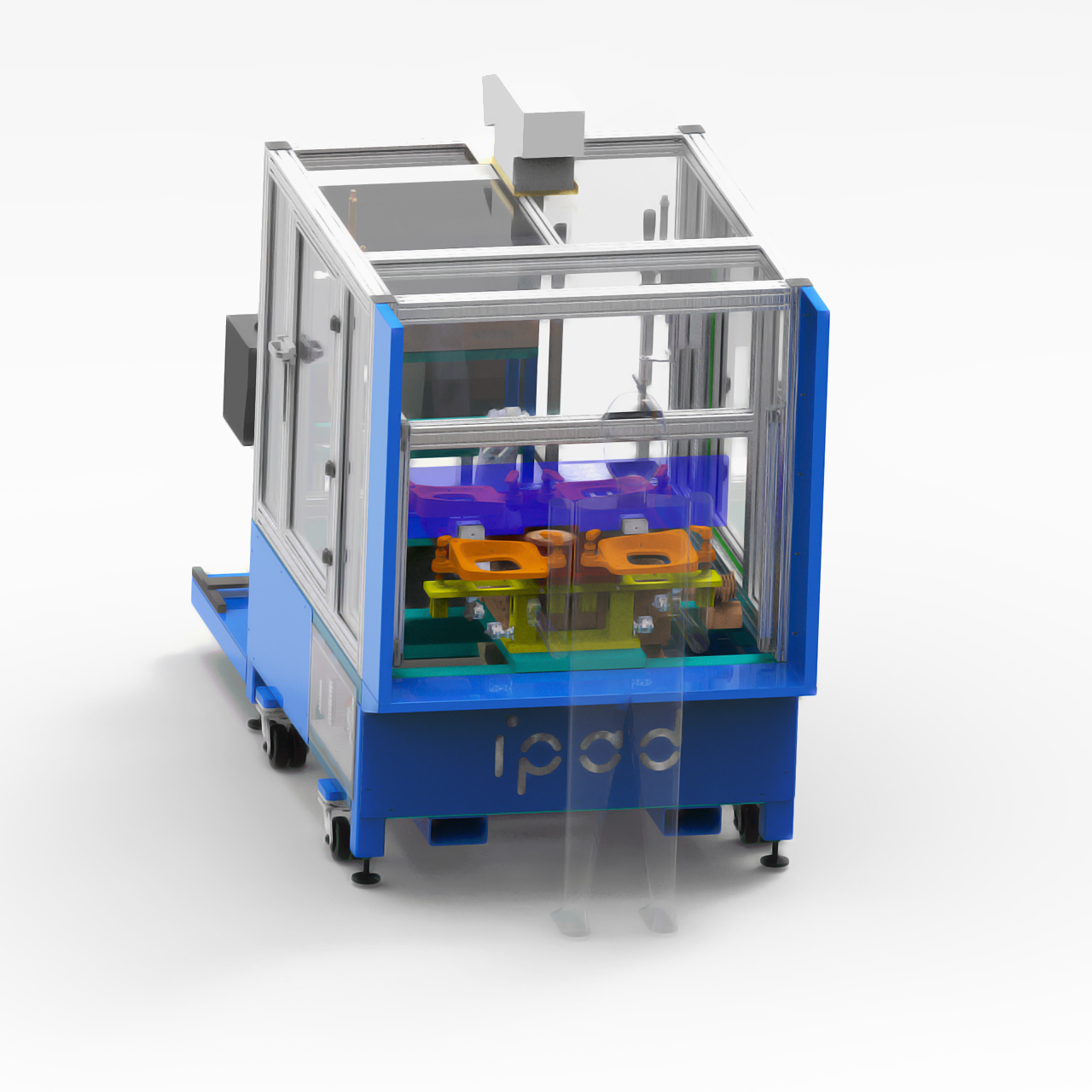

assembling cell for screws and car lamp components

This stand was built at the request of our customer to create an automatic cell for mounting the screws and the components of a car lamp. This workstation consists of: -robot kuka agilus 1100, a rotating table on which the working blades are mounted, screwdrivers with automatic feeding system provided with the control of the screwing torque and feed hopper.

The project’s priorities were: Improving benchmarks, reducing production costs, eliminating human errors.

The stand is made up of 2 work areas, a component supply area by the operator, and the robot work area.